Contact: Mr. Sun

Telephone: 0574-55846306/0574-55846307

Phone: +86 18868918868

Email address: sunquan198@163.com

Fax: 0574-55846308

Add: No.198 Qianjiao Road, Lingnan Industrial Zone, Beilun, Ningbo, China

Website: http://www.nbptjx.com

Alibaba website: shop1450529086289.1688.com

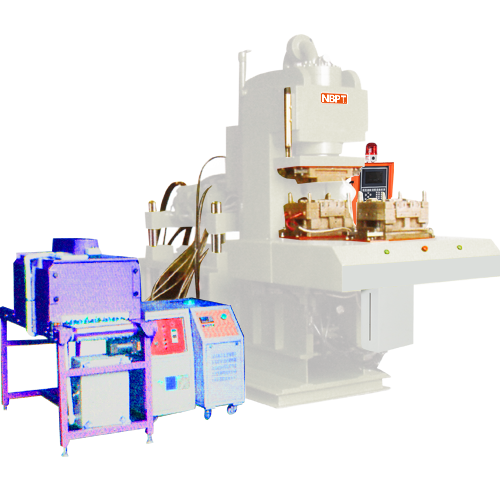

Vertical injection molding machine is a common injection molding machine in injection molding industry. It is mainly composed of injection system, mold closing system, hydraulic transmission system, electrical control system, lubrication system, heating and cooling system, safety monitoring system, etc. The operation is complex and complex, simple and simple, of course, more likely or what makes perfect. So many friends may ask, I bought a new injection molding machine should be how to debug it? Yes, after a new injection molding machine is installed, it must go through strict debugging procedures before it can be put into formal production. So how should it be debugged? Let's take a look. The debugging of vertical injection molding machine mainly includes the whole machine debugging, injection device debugging and mold device debugging. Today, I will focus on the debugging of the performance of the whole machine. There are mainly the following steps:

The debugging of vertical injection molding machine mainly includes the whole machine debugging, injection device debugging and mold device debugging. Today, I will focus on the debugging of the performance of the whole machine. There are mainly the following steps:

1. Check the hydraulic oil in the pressure tank and the oil level in the oiler to ensure that the hydraulic oil and lubricating oil are sufficient, and the type of oil should meet the requirements of the manual.

2. Switch on the main power supply, switch on the main switch on the control box, and place the operation mode selection switch on the point operation or manual operation. Start the standard vertical precision injection molding machine first to check whether the running direction of the oil pump is correct.

3. The machine should be started under the condition of no pressure of the hydraulic system, and then adjust the pressure of the hydraulic system to normal pressure after starting.

4. After the hydraulic pump works, open the cooling water valve of the oil cooler to cool the return oil and prevent the oil temperature from being too high.

5. After the hydraulic pump works for a short time, close the safety door and manually close the die, and open the pressure gauge to observe whether the pressure rises.

6. When the car is empty, manually operate the machine to run idling several times to observe whether the safety door, indicator light and various valve parts are correct and sensitive.

7. Check whether the relay, limit switch, counting device and total stop button work normally and reliably.

8. Carry out semi-automatic operation test run and automatic operation test run to check whether the operation is normal.

Is it easy? Believe that a lot of friends are eyes and brain tell you to say yes, but the hand said ruined. But you do not have to worry, if you do not have experienced master to operate, but also can ask the injection molding machine manufacturer guidance, if the distance is close to the case can also seek technical support from the manufacturer, is also possible, do not be afraid, brave and bold put forward your requirements to come.