Contact: Mr. Sun

Telephone: 0574-55846306/0574-55846307

Phone: +86 18868918868

Email address: sunquan198@163.com

Fax: 0574-55846308

Add: No.198 Qianjiao Road, Lingnan Industrial Zone, Beilun, Ningbo, China

Website: http://www.nbptjx.com

Alibaba website: shop1450529086289.1688.com

Blow molding machine will liquid plastic spray out, the use of the wind blown out of the machine, the plastic body blow attached to a certain shape of the mold cavity, so as to make products. The plastic is melted and quantitatively extruded in a screw extruder, then moulded through the mouth membrane, cooled by an air ring, then drawn at a certain speed by a tractor, and wound into coils by a winding machine.

Blow molding machines and moulds

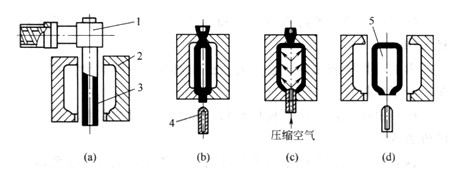

Blow Molding Machine and Mould (Fig. 1)

Blow molding machine can be divided into extrusion blow molding machine, injection blow molding machine and special structure blow molding machine three categories. Stretch and blow molding machines can be classified into each of the above categories.

Blow molding process principle

Blow molding process principle (Figure 2)

Extrusion blow molding will thermoplastic granule (or powder), after plasticizing through the extruder, through a specific die head, prepared into a hot melt shaped tubular billet, and then blow molding.

Injection blow molding using to open mold injected the parison on the mandrel, stay parison properly after cooling, the surface layers of parison curing, when moving mandrel not make the parison shape transformation or delay), the mandrel with the parison to blow molding mold, closes the blow molding mold, through the mandrel into the compressed air, make the parison huff and form required products, take out after cooling to finalize the design product.

Stretch and blow molding in a specific temperature range, so that the billet forced extension molding, molding at the same time, the wall of the product produced macromolecules in the direction of the arrangement and fixed down, thus greatly improving the performance of plastic containers. A forming method in which a base billet heated at an appropriate temperature below the melting point is placed in a mold and then blown immediately after axial stretching with a tensile rod.

Multilayer blow molding using multilayer composite billet, by blow molding process, the preparation of multilayer container molding method. Through the reasonable matching of various plastic layers, the effective complementarity of the plastic properties of each layer can be realized, so as to overcome some inherent shortcomings of single-layer plastic containers.